- Two-component adhesive

- Auto motive epoxy adhesive

- Epoxy adhesive for stone

- Structural adhesive

- Methacrylate adhesive

- Auto spare parts / Hardware

- Sealant adhesive

- Gasket maker

- Silicone sealant

- Fixing foam

- Light industrial / DIY glue

- Contact cement / neoprene glue

- Wood glue / white glue

- SBS adhesive / spray glue

- PVC glue

- Daily use glue adhesive

- Super glue / cyanoacrylate adhesive

- Adhesive tape

- Fly / mouse killing glue

Home > Notre information

This article mainly on the current market, the more commonly used three kinds of chemical products work a brief description, to help you understand the foam, sealant, glass glue properties and uses, differences, to help you better type selection.

The difference and connection between styrofoam, sealant and glass glue

At present, the common adhesive products, a variety of all, in order to be aimed at the wrong use, now the market is more mainstream glass glue, sealant and foam glue, and so on, and so on, the next small edition for everyone to briefly describe the differences and uses of these three products, performance;

The difference and connection between styrofoam, sealant and glass glue

1. Polyurethane foam filling agent (OCF), or styrofoam, foam gum:

It is the product of the combination of aerosol technology and polyurethane foam technology. It is a special polyurethane product which fills the polyurethane prepolymer, foaming agent, catalyst and other components into the pressure aerosol tank. When the material is ejected from the aerosol tank, the foamed polyurethane material expands rapidly and solidified with the moisture in the air or the contact matrix to form a foam. The solidified OCF foam has many kinds of effects, such as sealing, bonding, sealing, heat insulation and sound absorption. It is a kind of building material with environmental protection, energy saving and convenient use. It can be used for sealing, plugging, filling, sewing, fixing, bonding, thermal insulation and sound insulation. It is especially suitable for sealing, sealing and waterproofing of plastic steel or aluminum alloy doors and windows.

Usage: It can be used for sealing, insulating and filling wide joints, cracks and cracks. It can keep warm, resist cold, resist drying, sound insulation and moisture. Such as the gap between partitions and ceilings, the holes between window frames, doorframes, walls, the gaps between roofs and chimneys, the seals around walls, ceilings, pipe jacks, and the holes and damages in the walls. It can be used to bond many kinds of materials, such as metal, wood, stone, concrete and synthetic materials, such as polyester, polystyrene foam, PVC plastic, rigid polyurethane foam. The bison foam is not suitable for polyethylene, silicone and Teflon.

Two, sealant (also known as glass sealant, collectively referred to as glass glue):

It is a kind of sealing material which is deformed with the shape of the sealing cover and is not easy to flow and has certain caking property. The adhesive is used to fill the structural gap and play a sealing role. It also has the functions of leak proof, waterproof, anti vibration, sound insulation and heat insulation. The main raw materials are usually asphalt, natural resin or synthetic resin, natural rubber or synthetic rubber and other dry or non-dry viscous materials as the base material, with talc powder, clay, carbon black, titanium dioxide and asbestos and other inert fillers, plus plasticizers, solvents, curing agents, accelerators and other made.

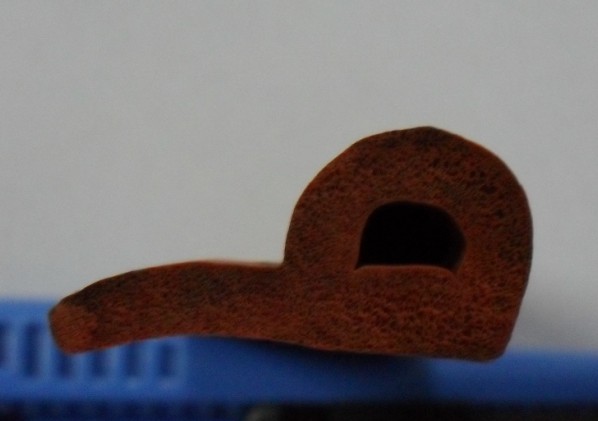

Classification: it can be divided into three categories: elastic sealant, liquid gasket and sealing putty.

Uses: widely used in building, transportation, electronic instruments and parts seal.

Building sealant is used to seal all kinds of joints or holes in buildings to prevent gas, liquid, solid penetration, to prevent structural materials from being damaged in structural displacement, thus playing a thermal insulation, sound insulation, waterproof, dust, gas, fire prevention, corrosion protection, shock absorption and prevention of joint accumulation of foreign bodies.

Three, glass glue (also known as glass sealant)

Glass glue is a commonly used home adhesive, the main ingredient is sodium silicate (Na2O mSiO2), soluble in water, viscous, also known as sodium silicate in the south, also known as the North alkaloids. Sodium silicate is a colorless, slightly colored, transparent or translucent viscous liquid in a water-based system. Solid sodium silicate is a colorless, slightly colored transparent or translucent glass block. Morphology is divided into three types: liquid, solid and water quenching. Theoretically, such substances are called colloids. Ordinary sodium silicate is a light blue bulk or granular solid, after high temperature and high pressure dissolution is a slightly colored transparent or translucent viscous liquid.

Subject classification:

1. The quality of glass glue can be inspected from the aspects of viscosity, pulling force, mildew proof, easy cleaning and discoloration. From the color point of view, glass glue has various colors, such as white, black, color, and transparent color.

2. Acidic silicone glass adhesives: a wide range of bonding, most of the building materials such as glass, aluminum, non-oily wood with excellent adhesion. But it can not be used for bonding ceramics, marble and so on.

3, neutral silicone glass glue: can be used for bonding ceramic sanitary ware, marble and so on.

4. There are many kinds of glass adhesives on the market, such as acid glass adhesives, neutral weatherproof adhesives, silicic acid neutral structural adhesives, silicone stone adhesives, neutral anti-mildew adhesives, hollow glass adhesives, aluminum-plastic board adhesives, aquarium adhesives, large glass adhesives, bathroom anti-mildew adhesives, acid structural adhesives and so on.

Main uses: suitable for general household sealant sealant, adhesive type glue, toilet and kitchen tabletop should be selected with mildew-proof glass glue, acidic or neutral; metal ceiling, shower room, mirror should be selected mildew-proof neutral glass glue, but not acid; smoke cooker kitchen appliances; Windows should be selected for weather neutral glass adhesives. The fish tank has high requirements for waterproof and adhesion properties of glass glue. Acidic structural sealant should be used.

From the above classification, in the market of foam, sealant, glass glue packaging, will indicate the material suitable for bonding, and some will also indicate the bonding strength of different materials when bonding, and so on. Users need to watch carefully, but also know more about the relative performance of the products used, construction conditions, notes. Items and so on, so as to make better selection.