- Two-component adhesive

- Auto motive epoxy adhesive

- Epoxy adhesive for stone

- Structural adhesive

- Methacrylate adhesive

- Auto spare parts / Hardware

- Sealant adhesive

- Gasket maker

- Silicone sealant

- Fixing foam

- Light industrial / DIY glue

- Contact cement / neoprene glue

- Wood glue / white glue

- SBS adhesive / spray glue

- PVC glue

- Daily use glue adhesive

- Super glue / cyanoacrylate adhesive

- Adhesive tape

- Fly / mouse killing glue

Home > Notre information

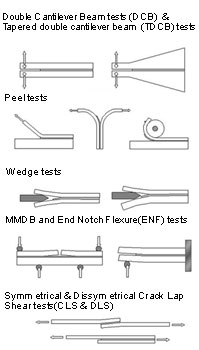

A wide range of testing devices have been imagined to evaluate the fracture resistance of bonded structures in pure mode I, pure mode II or in mixed mode. Most of these devices are beam type specimens. We will very shortly review the most popular:

Double Cantilever Beam tests (DCB) measure the mode I fracture resistance of adhesives in a fracture mechanics framework. These tests consist in opening an assembly of two beams by applying a force at the ends of the two beams. The test in unstable (i.e. the crack propagates along the entire specimen once a critical load is attained) and a modified version of this test characterised by a non constant inertia was proposed called the Tapered double cantilever beam specimen (TDCB).

Testing devicesPeel tests measure the fracture resistance of a thin layer bonded on a thick substrate or of two layers bonded together. They consist in measuring the force needed for tearing an adherent layer from a substrate or for tearing two adherent layers one from another. Whereas the structure is not symmetrical, various mode mixities can be introduced in these tests.

Wedge tests measure the mode I dominated fracture resistance of adhesives used to bond thin plates. These tests consist in inserting a wedge in between two bonded plates. A critical energy release rate can be derived from the crack length during testing. This test is a mode I test but some mode II component can be introduced by bonding plates of different thicknesses.

Mixed-Mode Delaminating Beam (MMDB) tests consist in a bonded bilayer with two starting cracks loaded on four points. The test presents roughly the same amount of mode I and mode II with a slight dependence on the ratio of the two layer thicknesses.

End Notch Flexure tests consist in two bonded beams built-in on one side and loaded by a force on the other. As no normal opening is allowed, this device allows testing in essentially mode II condition.

Crack Lap Shear (CLS) tests are application-oriented fracture resistance tests. They consist in two plates bonded on a limited length and loaded in tension on both ends. The test can be either symmetrical or dis-symmetrical. In the first case two cracks can be initiated and in the second only one crack can propagate.